The DETERGENT and WATER PROGRAM manages a double circuit powered by two electric pumps (detergent and water) that guarantee:

-

-

-

-

-

-

-

-

- A reduction of the environmental impact.

- A constant flow of solution

- A better quality of cleaning

- Avoid waste.

- A higher level of safety, avoiding detergent resides on the floor.

DETERGENT PROGRAM

DETER SAVER allows to keep the percentage of detergent proportionate to the required amount of water. Therefore, when the water flow rate changes, the program automatically increases or decreases the amount of detergent to maintain the required dilution percentage.

There are 5 different programs available, based on the percentage of dilution needed:

With DETER SAVER, it is possible to change the detergent type by simply replacing the tank. The tank has a capacity of 3 or 5 liters, depending on the model, and it is provided with a label where the most important information can be reported.

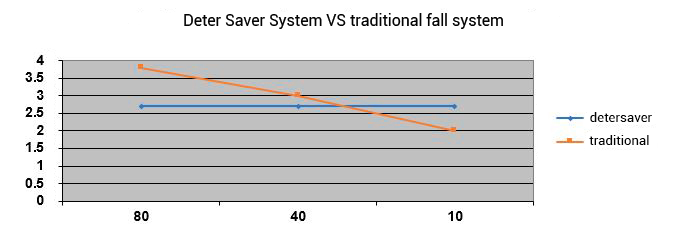

The integrated system ensures a continuous water and detergent flow to maintain a constant cleaning quality.The following graph shows the difference in supply between the DETER SAVER system and the traditional fall system (flow by gravity). With the traditional fall system, a decrease in flow is shown in relation to the lower volume of water in the tank.

SUSTAINABLE CLEANING

The use of DETER SAVER meets the criteria of environmental sustainability thanks to the possibility to select the minimum percentage of detergent and water required according to specific conditions, ensuring constant cleaning over time.

In addition, it is programmed to reduce water and detergent waste, in fact, if the operator stops working, the brushes automatically stop too, and the solution flow is interrupted immediately.

In this way, the use of detergents, the number of plastic cans containing the chemical products, and the transports are reduced, all of which add up to limit the environmental impact.

ADVANTAGES

Thanks to the use of DETER SAVER, the following advantages are achieved:

- Reliable use of detergent and water per square meter, thanks to the possibility to select the desired pre-set parameters.

- Definite cost of detergent consumption per square meter: the system guarantees a constant use of the detergent and avoids possible dosing errors or negligence by operators.

- Savings in detergent are possible thanks to the opportunity to vary, during work and without wasting time, the percentage of detergent according to the actual amount of dirt present.

- Respect for the environment and more aware management of resources: reduce the use of detergents and allow for the selection of the minimum quantity according to the conditions of the floor. It limits the use of water by adjusting it according to the dirt present and ensuring consistency over time. It interrupts the flow of solution to stop the brushes, avoiding unnecessary waste and having a lower environmental impact.

- Higher working efficiency is guaranteed by the constant water and detergent flow and the elimination of the time required for detergent dosing.

- Higher cleaning quality: the constant emission of water and detergent keeps the washing capacity unchanged from the beginning to the end of the work shift, regardless of the amount of water present in the tank.

- Higher level of safety: the operator reduces the possibility of accidental contact with chemical detergents.

- Change of detergent type: using the scrubber in situations where specific detergents are required, it is possible to pass quickly (saving time) from one detergent to another without having to:

- Empty the tank from the unused solution (economic and environmental impact)

- Rinse the solution tank if the detergents are incompatible (saving time for the operator)

- Refill the tank with water (saving time for the operator)

- Dose again the detergent solution (saving time, avoiding errors and avoiding the negligence of the operator).